158-5772-7166

PRODUCT NAME:

|  |

1. Performance characteristics of QJB submersible mixer

1. QJB submersible mixer has compact structure, simple operation and maintenance, convenient installation and maintenance, and long service life.

2. The impeller has the best hydraulic design structure and high working efficiency. The swept-back blade has a self-cleaning function to prevent entanglement and blockage of debris.

3. Mixed use with aeration system can greatly reduce energy consumption, increase oxygenation capacity significantly, and effectively prevent precipitation.

4. The insulation class of the motor winding is F, and the protection class is IP68. Imported bearings and a unique patented motor anti-condensation device are selected to make the motor work safer and more reliable.

5. Two mechanical seals, made of tungsten carbide-tungsten carbide. All exposed fasteners are stainless steel

2. Model meaning of QJB submersible mixer

Low-speed push-flow mixers are suitable for aeration tanks and anaerobic tanks of industrial and urban sewage treatment plants. They produce strong water flow with low tangential flow, which can be used for water circulation in the pool and water flow in the stages of nitrification, denitrification and phosphorus removal.

3. Product use of QJB submersible mixer

The mixing and mixing series mixers are suitable for mixing liquids containing suspended solids in sewage treatment plants and stations.

Low-speed push-flow mixers are suitable for aeration tanks and anaerobic tanks of industrial and urban sewage treatment plants. They produce strong water flow with low tangential flow, which can be used for water circulation in the pool and water flow in the stages of nitrification, denitrification and phosphorus removal.

Fourth, the scope of application of QJB submersible mixer

The QJB submersible mixer should be able to operate normally and continuously under the following conditions

1. The highest medium temperature does not exceed 40℃;

2. The PH value of the medium is between 5 and 9;

3. The density of the liquid does not exceed 1150kg/m3;

4. For long-term diving operations, the diving depth generally does not exceed 20m.

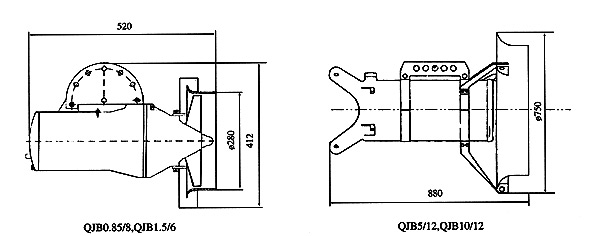

Five, QJB type submersible mixer structure diagram

Six, QJB type submersible mixer selection precautions

In order to ensure the best results, the user is requested to provide the following information:

1. Purpose of use

2. Pool type

3. Pool size

4. Media characteristics include viscosity, density, solid content, etc.

5. The matching power required by the mixer is determined according to the volume, the density, viscosity and the depth of the mixing liquid. One or more mixers should be used according to the specific situation.

6. The mixer must be completely submerged in water to work, and cannot work in an flammable and explosive environment or an environment with strong corrosive liquids.

7. For selection issues, please contact the supplier.

Seven, QJB type submersible mixer model meaning

QJBO.85/8-260/3-740/C/S/P/AL

QJB—Submersible mixer

O.85—Motor power

8—Number of motor stages

260—impeller diameter

3—Number of impellers

740- impeller speed

Material: C-cast iron S-stainless steel P-polyurethane AL-aluminum

8. Technical performance table of QJB submersible mixer

搅拌机型号 | 额定功率 | 额定电流 | 叶轮直径 | 叶轮轮速(r/min) | 重量(kg) | |

(kw) | (A) | (mm) | ||||

Casting mixer | QJBO.85/8-260/3-740/C/S | 0.85 | 4 | 260 | 740 | 55 |

QJB1.5/6-260/3-960/c/s | 1.5 | 4 | 260 | 960 | 55 | |

QJB2.2/8-320/3-740/c/s | 2.2 | 5.9 | 320 | 740 | 110 | |

QJB4/6-320/3-960/c/s | 4 | 10.3 | 320 | 960 | 115 | |

QJB5.5/4-670/3-295/c/s | 5.5 | 11.3 | 670 | 295 | 350 | |

QJB7.5/4-670/3-330/c/s | 7.5 | 15 | 670 | 330 | 360 | |

QJB11/4-790/3-303/c/s | 11 | 23.4 | 790 | 303 | 400 | |

QJB15/4-790/3-360/c/s | 15 | 29.7 | 790 | 360 | 41 | |

Punch mixer | QJB1.5/8-400/3-740/s | 1.5 | 4.4 | 400 | 740 | 100 |

QJB2.5/8-400/3-740/s | 2.5 | 7 | 400 | 740 | 100 | |

QJB3/8-400/3-740/s | 3 | 8.6 | 400 | 740 | 100 | |

QJB4/12-615/3-480/s | 4 | 18 | 615 | 480 | 184 | |

QJB5/12-615/3-480/s | 5 | 20 | 615 | 480 | 184 | |

QJB7.5/12-615/3-480/s | 7.5 | 28 | 615 | 480 | 229 | |

QJB10/12-615/3-480/s | 10 | 32 | 615 | 480 | 229 | |

Low-speed push-flow mixer | QJB3/2-1100/2-135/P | 3 | 6.4 | 1100 | 135 | 135 |

QJB1.5/4-1800/2-42/P | 1.5 | 3.6 | 1800 | 42 | 158 | |

QJB2.2/4-1800/2-50/P | 2.2 | 4.9 | 1800 | 50 | 162 | |

QJB3/4-1800/2-56/P | 3 | 6.8 | 1800 | 56 | 162 | |

QJB4/4-1800/2-65/P | 4 | 8.8 | 1800 | 65 | 165 | |

QJB1.5/4-2500/2-36/P | 1.5 | 3.6 | 2500 | 36 | 170 | |

QJB4/4-2500/2-42/P | 4 | 8.8 | 2500 | 42 | 185 | |

QJB5/4-2500/2-56/P | 5 | 11 | 2500 | 56 | 185 | |

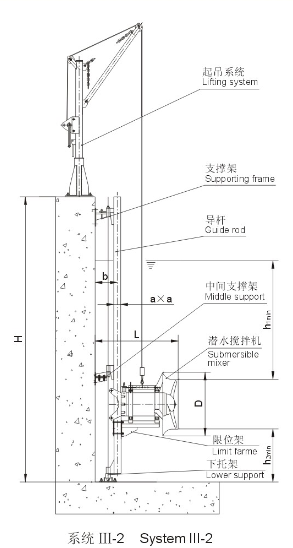

9. QJB type submersible mixer installation system diagram

Installation requirements for submersible mixers: guide rods, wire ropes, and lifting systems must be kept parallel

Operation mode diagram of submersible mixer: