158-5772-7166

PRODUCT NAME:

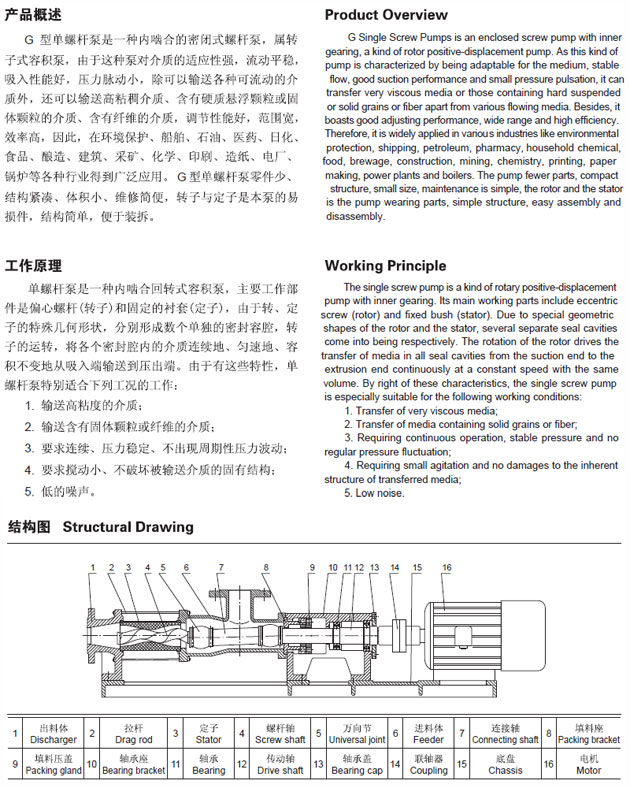

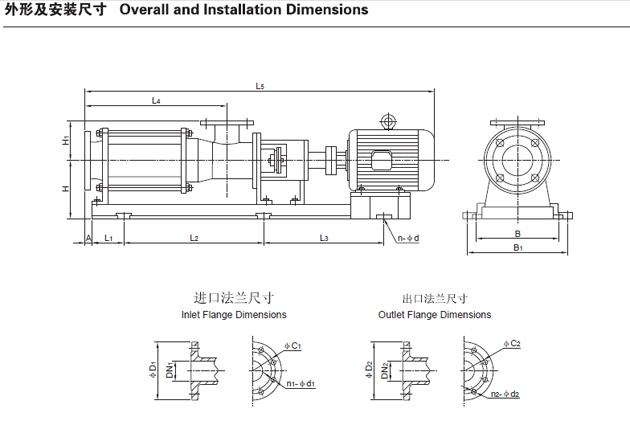

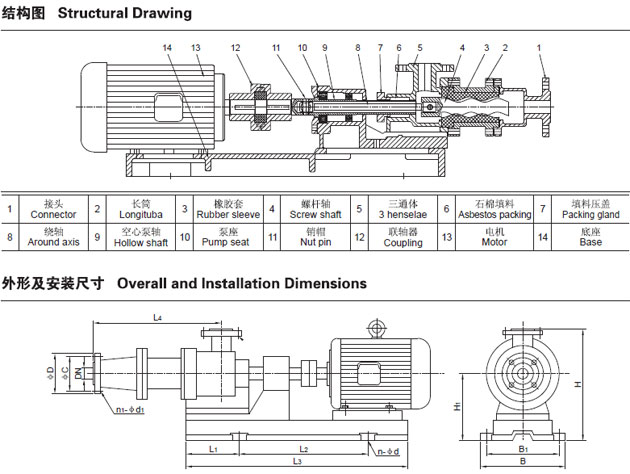

G-type single screw pump [1] is a rotor type positive displacement pump, which relies on the screw and bushing to mesh with each other to produce volume changes in the suction cavity and discharge cavity to transport liquid. It is a closed screw pump with internal meshing. The main working parts are composed of a bushing (stator) with a double-head spiral cavity and a single-head spiral screw (rotor) meshing with it in the stator cavity. When the input shaft drives the rotor through the universal joint to make a planetary rotation around the center of the stator, the stator-rotor pair is continuously meshed to form a sealed cavity. The volume of these sealed cavities will move in an axial direction at a constant speed to transfer the medium from the suction end through the stator. — The rotor pair is transported to the extrusion end, and the medium sucked into the closed cavity flows through the stator without being agitated or damaged.

The inner surface of the bushing has double threads, and its arbitrary cross-section is an oblong circle, the two ends are semicircles with a radius of R (equal to the radius of the screw section), and the middle is a straight line segment with a length of 4e. Any cross-section of the bushing is the same ellipse, but is staggered from each other by an angle.

After the screw is installed in the bushing, a closed cavity is formed between the screw surface and the inner thread surface of the bushing, and any cross-section is also divided into two crescent-shaped working chambers. When the screw rotates, the volume of the first working chamber close to the suction chamber gradually increases, forming a negative pressure, and the liquid is sucked into the working chamber under the action of the pressure difference. As the screw continues to rotate, the volume of the working chamber continues to increase to the maximum, the working chamber is closed, and the liquid is pushed out of the chamber along the axial direction. At the same time, the upper and lower working chambers suck and discharge the liquid alternately, so the liquid is continuously pushed from the suction chamber to the press-out chamber in the axial direction.

Compared with piston pump centrifugal pump, vane pump and gear pump, G type single screw pump has many advantages as follows:

1. It can transport media with high solid content;

2. Uniform flow and stable pressure, more obvious at low speed;

3. The flow rate is proportional to the speed of the pump, so it has good variable adjustability;

4. One pump for multiple purposes can transport media of different viscosities;

5. The installation position of the pump can be tilted arbitrarily;

6. Suitable for conveying sensitive items and items that are easily damaged by centrifugal force;

7. Small size, light weight, low noise, simple structure and convenient maintenance [2].