158-5772-7166

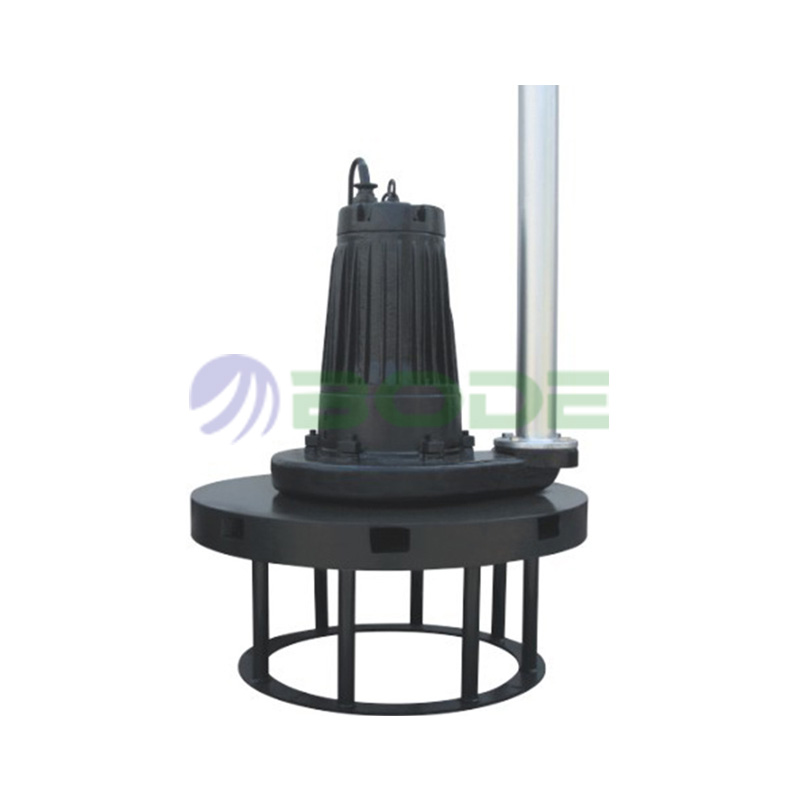

PRODUCT NAME:

One. Working principle of QXB centrifugal aerator

The QXB centrifugal aerator adopts the direct drive of the motor and the impeller, and uses the centrifugal force generated by the rotation of the impeller to displace the surrounding water to form a low-pressure zone to inhale water. At the same time, create a vacuum at the impeller entrance to inhale air, and the air and water in the mixing chamber are sufficient. It is mixed to form a uniform gas-water mixture, which is quickly discharged under the action of centrifugal force.

Due to the strong jet of water, the circulation of water caused the air to be sheared into a large number of tiny bubbles. The surface area is greatly increased, and a large amount of oxygen in the air is dissolved in the water due to the slow rise of bubbles, which makes the machine's power efficiency better than other types of aerators.

Two. Application scope of QXB centrifugal aerator

The QXB centrifugal aerator is used in aeration tanks and aeration grit chambers of sewage treatment plants to aerate and mix the mixed liquid of sewage, and to conduct biochemical treatment of sewage or aeration in aquaculture ponds. The carrying capacity is 10~100m3, the aeration capacity is 0.35~8.20KgO2/h, and the motor power is 0.75~22kw.

Three, QXB type centrifugal aerator structure characteristics

1. Use the underwater motor that introduces the Flygt submersible motor sealing technology;

2. The impeller is directly connected to the motor, with simple structure, high efficiency and long life;

3. A mesh water inlet can be added to avoid damage caused by foreign matter entering the body;

4. The intake air volume can be adjusted through the intake valve;

5. In addition to the motor, the materials of other parts are available in stainless steel, carbon steel and cast iron.

Four, QXB type centrifugal aerator characteristics

1. The air mixing chamber is designed with a large amount of inhaled air, good mixing effect and high oxygen utilization rate;

2. The gas-water mixture is discharged from the mixing chamber at a special angle, which can make the water flow spirally to the horizontal direction and then flow upwards, and it has a stirring effect at the same time as aeration;

3. The machine body is submerged in water and runs without noise. A muffler can be installed on the water outlet surface of the air intake pipe to enhance the muffler effect.

5. Technical parameters of QXB centrifugal aerator

| model | power | Scope of action(m) | Maximum diving depth | Air suction pipe diameter(mm) | Air intake(m3/h) |

| QXB1.5-40 | 1.5 | 1.0-20 | 2 | 40 | 22 |

| QXB2.2-50 | 2.2 | 2.5-50 | 3 | 50 | 35 |

| QXB3-50 | 3 | 3.0-5.5 | 3 | 50 | 30 |

| QXB4-65 | 4 | 3.0-6.0 | 3 | 65 | 75 |

| QXB5.5-65 | 5.5 | 3.5-7.0 | 3 | 65 | 85 |

| QXB7.5-80 | 7.5 | 4.5-9.0 | 3 | 80 | 100 |

| QXB11-80 | 11 | 5.0-10.0 | 4 | 80 | 160 |

| QXB15-100 | 15 | 5.8-11.5 | 5 | 100 | 200 |

| QXB18.5-100 | 18.5 | 5.9-11.8 | 5.5 | 100 | 260 |

| QXB22-100 | 22 | 6.0-12.0 | 6 | 100 | 320 |